What is sport welding and how to spot welding? Spot welding is a process that is used to join two pieces of metal together. It is a fast and efficient way to create solid and durable joints. However, there are some drawbacks to spot welding, such as the fact that it is limited to thin materials. In addition, spot welding requires specialized equipment.

If you are considering spot welding for your next project, here are some things to keep in mind:

1. The type of materials you will be working with

2. The thickness of the materials

3. Your budget for the project

What is Spot Welding

Spot welding is a type of welding in which the materials are compressed at the point where the two pieces being welded together come into contact. The welded metal resolves, creating a solid joint between the two pieces.

The Drawbacks of Spot Welding

Spot welding is frequently used on materials with thicknesses ranging from 0.01 to 3 millimeters (depending on the machine). Depending on the process, some spot welding machines use heat, making it difficult to weld thicker materials without causing damage.

Can Cause Distortion

Because some spot welding machines produce localized heat, the welded material can be distorted. This is especially true for thin materials, which are more susceptible to heat damage. Distortion can be minimized by using an ultrasonic spot welding machine which uses ultrasonic vibrations with lower power and higher frequency. This helps in preventing foil breaks and crack by reducing stress while keeping the weld time as short as possible.

The Benefits of Ultrasonic Spot Welding

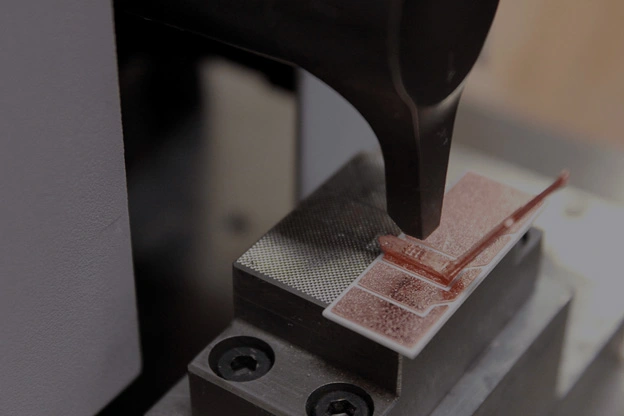

Many people having the question in mind, how to spot welding and what are the benefits of it? Ultrasonic spot welding is a robust and reliable joining method that creates strong, durable joints between two pieces of metal. The high pressure in ultrasonic spot welding compresses the metals together, creating a bond much more robust than an adhesive or welded joint. This makes ultrasonic spot welding ideal for applications where strength and durability are paramount, such as in the automotive industry. Ultrasonic spot welding is commonly used in the manufacturing of lithium battery welding used in mobile phones, credit cards, and electric vehicles to join foil stacks, foil-to-tab, and foil-to-bubar. It is also used in the manufacturing of appliances and other consumer goods.

This ultrasonic welding method is a fast and efficient way to create strong joints between two pieces of metal. It is a popular choice for manufacturing applications.

Fast and Efficient

Ultrasonic spot welding is a fast and efficient way to join two pieces of metal together. The entire process can be completed in just a few seconds, making it ideal for mass-production applications. It also prevents cracks and foil breaks by reducing stress, and ultrasonic vibration causes no coating damage. Additionally, ultrasonic spot welding is a relatively simple process that does not require highly skilled labor, making it more cost-effective than other joining methods.

Cost-Effective

Ultrasonic spot welding is a cost-effective joining method for many applications. The equipment required for ultrasonic spot welding is expensive, but the process itself is fast and requires little labor. Ultrasonic spot welding is an attractive option for companies looking to reduce costs without compromising quality or speed.

How to Choose the Best Spot Welding Machine

The type of material you will be welding will play a significant role in determining which spot welding machine is suitable for you.

Thickness

The thickness of the material you are welding will also play a role in determining which machine is suitable for you. If you are welding thin materials, a lower-powered device may be sufficient. However, if you are fusing thicker materials, you will need a more powerful machine.

Budget

Finally, your budget will also play a role in determining which spot welding machine suits you. There are many different machines on the market, and they vary widely in price. Before making a purchase, you’ll need to decide how much you will spend on a device.

Conclusion

Hope now you know how to spot welding. Ultrasonic spot welding is an excellent option for joining two pieces of metal together quickly and efficiently. However, it is crucial to take into account the type of materials you are working with, their thickness, and your budget. Consider investing in Advanced Servo-Controlled Ultrasonic Metal Welding Machines to ensure the best results.

TECH-SONIC’s Closed Loop Control Welding process is designed to provide superior results and is backed by a team of experts. Contact them today to learn more and find out how they can help you with your next project!

Read also

What Does Voltage Do in Mig Welding?

How To Get The Best Budget Welding Machine?

I love all things tech, and I wear many hats – tech lover, business starter, digital marketer, and blogger. I know the ins and outs of Digital Marketing, SEO, SEM, SMM, and how to generate leads. My goal? Making things simple for you with clear guides and reviews. I stumbled upon WordPress while creating my first business site, and I fell in love with it right away. When I’m not building websites, creating content, or boosting clients’ online efforts, I’m focused on staying healthy, hanging out with family, and exploring the world. Connect with me on Facebook, Twitter, Linkedin, or read my complete biography.