The date of the launch of the new product has been announced. As the engineer of the company, you are scrambling to get the blueprints ready for the manufacturers. The hardest part of the job is to move the products from paper to the product so that the company can market them before the competitors do. The deadlines are hanging over your head, and it’s a crime if you are going to miss the date.

But before you panic, you need to identify the mission-critical parts that are essential to the business. You need to know which products need prioritizing and identify those that can be delayed. The critical components are what make a company going for a long time. If there are accidents and the essential parts are missing, then this can spell disaster.

When you are committing to the production of the critical parts, you need to validate the designs that you have through the process of prototyping. This will immensely help you resolve the issues in the initial phase and if an item is a critical component of the whole project. For you to do this efficiently, you need a partnership with a machine shop that can provide you with the things that you need to meet your deadline.

How to Choose the Right Company

A prototype company will understand what you need and will deliver the results according to your specifications. They can do the prototype process and mission critical part manufacturing and protects your intellectual property in the process. They can also produce lots of components in the shortest time possible while keeping the costs low. What you are looking for in other words is a business that will help solve your problems – not create one during a prototype work. Here are some of the criteria to consider that will narrow your field:

1. Experience with your Industry

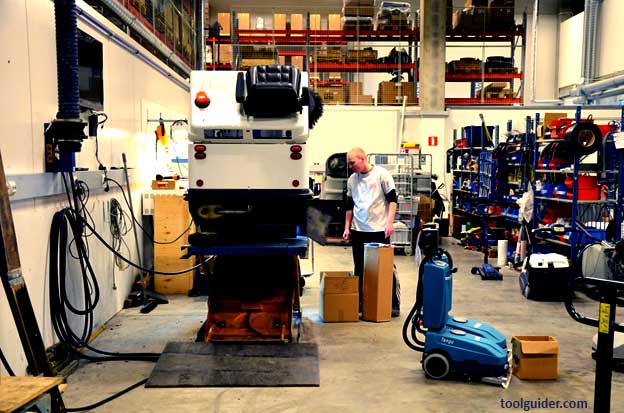

You need a prototyping company that has plenty of experience in your niche. If you are in the business of making car parts or factory machine accessories, you also need a shop that knows everything going on in your industry. They need to know which types of materials to use, the limitations, benefits, and applications of the parts that you have in mind. They also need to have in-house operations and state-of-the-art machines that will make the whole process a breeze.

If the company that you find speaks the language in your industry, then consider them a good find. The experienced engineers can walk you through into the prototyping process and will communicate with you every stage of the manufacturing process.

2. Capable of End-to-End Prototypes

In an ideal scenario, you need a machine shop that can help you bring your designs to life. They need to have a machine that can create your specifications. They should also be working under one roof so that a single team oversees all the activities, and the overall product is cohesive to the original design. Most of the machines today are capable of plastic injection molding and CNC machining. You can know more about the process of plastic injection molding when you click here.

A single tool that can do most of your requirements will help you big time. You don’t need to waste time contacting different people located in many places. The components and the assemblies are done in one location before they are shipped to you. You don’t have time to waste since your competitors are doing all they can to get your clients. It’s essential to have only one company handle all your transactions so that you can avoid problems with changes, and you can coordinate the complexities of the parts without the extra headache.

Another benefit that you can get with end-to-end companies is that they can protect and secure your job. This means that they won’t disclose this to your competitors, and you solely have the right to the finished project. IP theft is a likely scenario when many people are handling your project. If you limit the number of eyes that will see your plans and blueprints, the less likely they will fall in the hands of your biggest competitor.

3. They Invest in Technology

Technology is an ever-changing industry, and companies need to keep up. When they invest in machines that can make prototyping and CNC work in a matter of hours, they can increase workability at the same time. This translates to quicker turnaround times of the mission-critical components that you need.

Search for prototyping companies that aim to create high-quality 3D models made up of premium materials. Investing in high-end machinery means that the resulting prototype prints are free from any kinds of errors, such as missing drill holes. There should not be any defects, and the manufacturer should get everything right. A functional prototype is one where the staff knows how to use the machinery, and there should be a dedicated section that caters to the requests and changes that you need.

4. They Have Quicker Turnaround Times

The date when you will be receiving your prints is significant. The order date and the shipping should not exceed two weeks. Most of the projects should be finished on time. This could be achieved with the constant communication, setting clear expectations, and working on the project on time.

Most clients prefer the providers for faster delivery dates since competition out there is fierce. If you are one of the business owners who want to jumpstart your business, you need to have your designs ready and be able to gauge how your market will react. If there’s room for improvement, you should be able to contact your machinery shop to make the necessary adjustments. Quicker turnaround time, as well as speedily responding to changes, are keys to success.

If you are planning to outsource the manufacturing of your parts, then a reputable company can help you. They are one of the keys to making your business grow and for you to stay ahead of the competition. So you need to choose well. Hope it will help you to learn how to choose the right company.

I love all things tech, and I wear many hats – tech lover, business starter, digital marketer, and blogger. I know the ins and outs of Digital Marketing, SEO, SEM, SMM, and how to generate leads. My goal? Making things simple for you with clear guides and reviews. I stumbled upon WordPress while creating my first business site, and I fell in love with it right away. When I’m not building websites, creating content, or boosting clients’ online efforts, I’m focused on staying healthy, hanging out with family, and exploring the world. Connect with me on Facebook, Twitter, Linkedin, or read my complete biography.

Trackbacks/Pingbacks